Engine Testing

Home > Solutions > Turnkey > Conventional Powertrain > Conventional ICE

Accelerate Engine Excellence with Precision Testing.

ALWAYS AT THE SIDE OF OUR CUSTOMERS

Challenges

Achieving optimal engine performance while meeting stringent emission regulations is a major challenge for manufacturers. Traditional testing methods often lack precision, real-world simulation, and integration, leading to inefficiencies, compliance risks, and higher costs. Without advanced testing solutions, validating engine durability, fuel efficiency, and emission standards becomes complex and time-consuming.

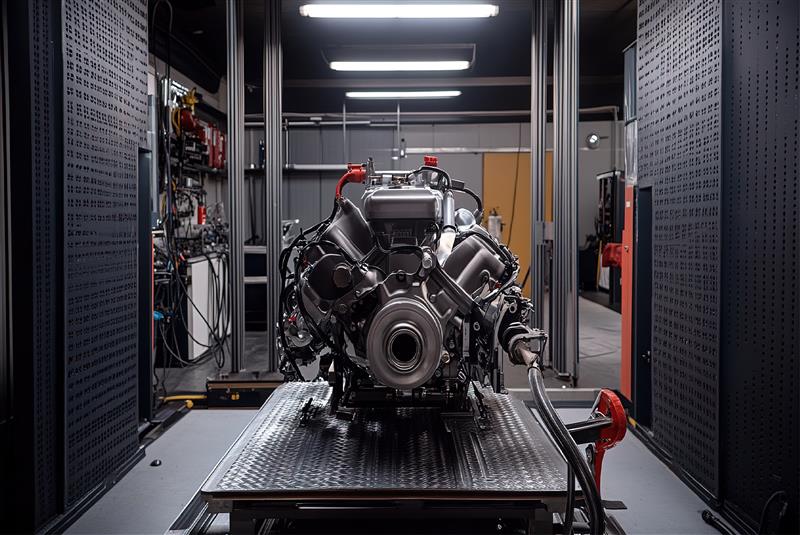

R&D Engine

Pain Points

Without advanced and integrated testing solutions, achieving optimal engine performance and meeting regulatory requirements becomes a significant hurdle.

- Engine manufacturers face challenges in accurately simulating real-world conditions to validate engine performance, durability, and compliance with stringent emission standards.

- Traditional testing methods often lack the precision and integration required for modern engine development, leading to inefficiencies and potential non-compliance.

Remedies

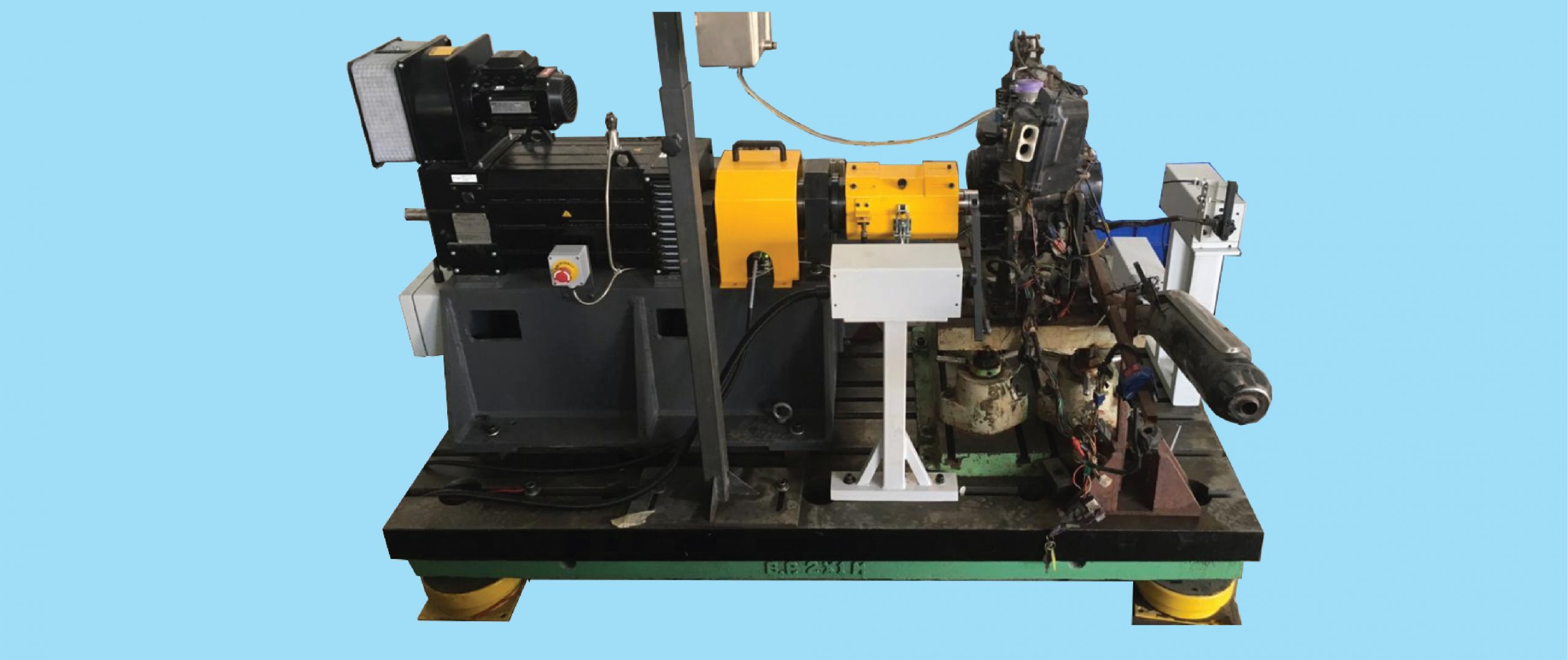

Engine Testing Solutions are designed to emulate real-world conditions, ensuring comprehensive performance evaluations and regulatory compliance. Our Transient Engine Test Bench and Orbit-E Automation System provide a cohesive platform for precise, efficient, and safe engine testing, tailored to the evolving needs of the automotive industry.

-

Delivers dynamic test cycles with high precision, enabling thorough evaluations of engine components under simulated real-world conditions.

- Supports execution of all European and Indian legislative cycles up to EURO VI and BS VI, ensuring engines meet global emission standards.

- Captures transient behaviors with data logging frequencies up to 1 kHz, facilitating detailed analysis and informed decision-making.

Integrated Testing Environment

-

Allows seamless integration with various testing devices, promoting a cost-effective and flexible approach to engine testing.

-

Generates reports compliant with legislative standards, customizable to specific customer needs, enhancing transparency and compliance.

- Offers expertise in test cell mechanics, providing comfortable and flexible test cell architectures that enhance operational efficiency.

- Implements multiple safety precautions to protect both the UUT and test cell components, ensuring a secure testing environment.

Key Features

Performance Evaluation

Real-World Emulation

Efficient Automation

Regulatory Compliance

Safety

Increased Accuracy

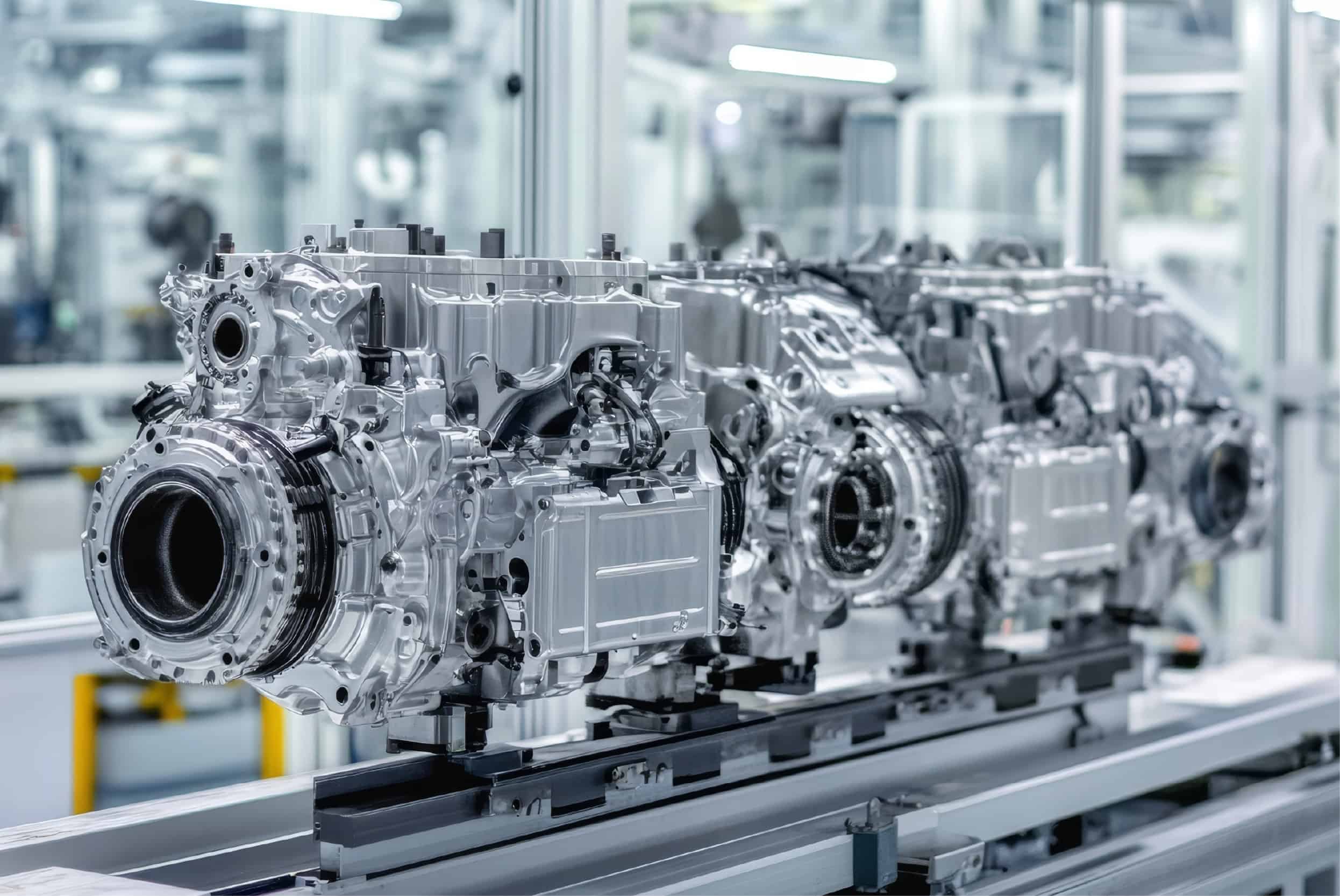

Production Engine

End-of-Line Validation.

Our End-of-Line (EOL) Testing Solutions guarantee that each Engine meets the highest standards of performance, durability, and compliance before it exits the production line. Engineered for efficiency and reliability, our automated systems feature real-time monitoring, advanced diagnostics, and seamless data connectivity to provide accurate and consistent validation.

- Energy-Efficient – Optimized track time for minimal power consumption.

- Reliable System – Ensures consistent and accurate testing results.

- Easy Diagnostics – Quick identification and resolution of issues.

- Data Traceability – Secure storage and connectivity for test data.

- User-Friendly – Intuitive interface for effortless operation and maintenance.

Featured Insights

Case Study on HVDT FFT Analysis for Catcon Exhaust System Validation

November 11, 2025

Case Study

This case study showcases how iASYS enabled a leading automotive

manufacturer to validate its Catcon exhaust system using an

advanced HVDT FFT analysis approach. Through the integration of

the Orbit…

Read More

Case Study

Turnkey Testing Solutions

May 6, 2022

Case Study

iASYS developed an end of line test bed/Rig for one of the leading Auto maker to test their engines in a given timeframe…

Read More

Blog

Ensuring the Successful Implementation of a Smart Test Bed

October 18, 2022

Blog

As the world around us becomes embroiled in VUCA, organizations and industries globally look for ways to improve resilience and responsiveness in their business. The rise of technologies such as AI…

Read More

Blog

Many Benefits of a Smart Test Bed for Manufacturing Facilities

October 11, 2022

Blog

The rise of Industry 4.0 has ushered in the era of smart manufacturing, an age defined by elevated efficiency and less waste. New technologies are pushing organizations to drive the digital…

Read More

Solution Documents

Gear Shift Robot for Powertrain Dyno GSR2020

August 13, 2021

Solution Documents

A gear shift robot for a powertrain dyno is created using an understanding of human driving behavior. Robots can schedule data on vehicle characteristics and speed based on their operational cycles…

Read More

Solution Documents

Transient Engine Testing

August 13, 2021

Solution Documents

Transient Engine Testing (TREM 4), First time in India by an Indian Company…

Read More

Solution Documents

Transient Engine Testing (TREM 4)

August 6, 2021

Solution Documents

Transient Engine Testing (TREM 4), First time in India by an Indian Company…

Read More

Product Leaflet

Transient (AC) Dynamometer

May 16, 2022

Product Leaflet

iASYS Transient series AC Dynamometers are specifically made for testing engines. It works closely with a speed and torque measuring device that is extremely accurate, giving it the capacity to…

Read More

Case Study

Case Study on HVDT FFT Analysis for Catcon Exhaust System Validation

November 11, 2025

Case Study

This case study showcases how iASYS enabled a leading automotive

manufacturer to validate its Catcon exhaust system using an

advanced HVDT FFT analysis approach. Through the integration of

the Orbit…

Read More

Case Study

Turnkey Testing Solutions

May 6, 2022

Case Study

iASYS developed an end of line test bed/Rig for one of the leading Auto maker to test their engines in a given timeframe…

Read More

Blog

Ensuring the Successful Implementation of a Smart Test Bed

October 18, 2022

Blog

As the world around us becomes embroiled in VUCA, organizations and industries globally look for ways to improve resilience and responsiveness in their business. The rise of technologies such as AI…

Read More

Blog

Many Benefits of a Smart Test Bed for Manufacturing Facilities

October 11, 2022

Blog

The rise of Industry 4.0 has ushered in the era of smart manufacturing, an age defined by elevated efficiency and less waste. New technologies are pushing organizations to drive the digital…

Read More

Solution Documents

Gear Shift Robot for Powertrain Dyno GSR2020

August 13, 2021

Solution Documents

A gear shift robot for a powertrain dyno is created using an understanding of human driving behavior. Robots can schedule data on vehicle characteristics and speed based on their operational cycles…

Read More

Solution Documents

Transient Engine Testing

August 13, 2021

Solution Documents

Transient Engine Testing (TREM 4), First time in India by an Indian Company…

Read More

Solution Documents

Transient Engine Testing (TREM 4)

August 6, 2021

Solution Documents

Transient Engine Testing (TREM 4), First time in India by an Indian Company…

Read More

Product Leaflet

Transient (AC) Dynamometer

May 16, 2022

Product Leaflet

iASYS Transient series AC Dynamometers are specifically made for testing engines. It works closely with a speed and torque measuring device that is extremely accurate, giving it the capacity to…

Read More

Let's Solve it together

Struggling with complex Testing and Validation tasks?

They trust us