Brix -Lab Digitization

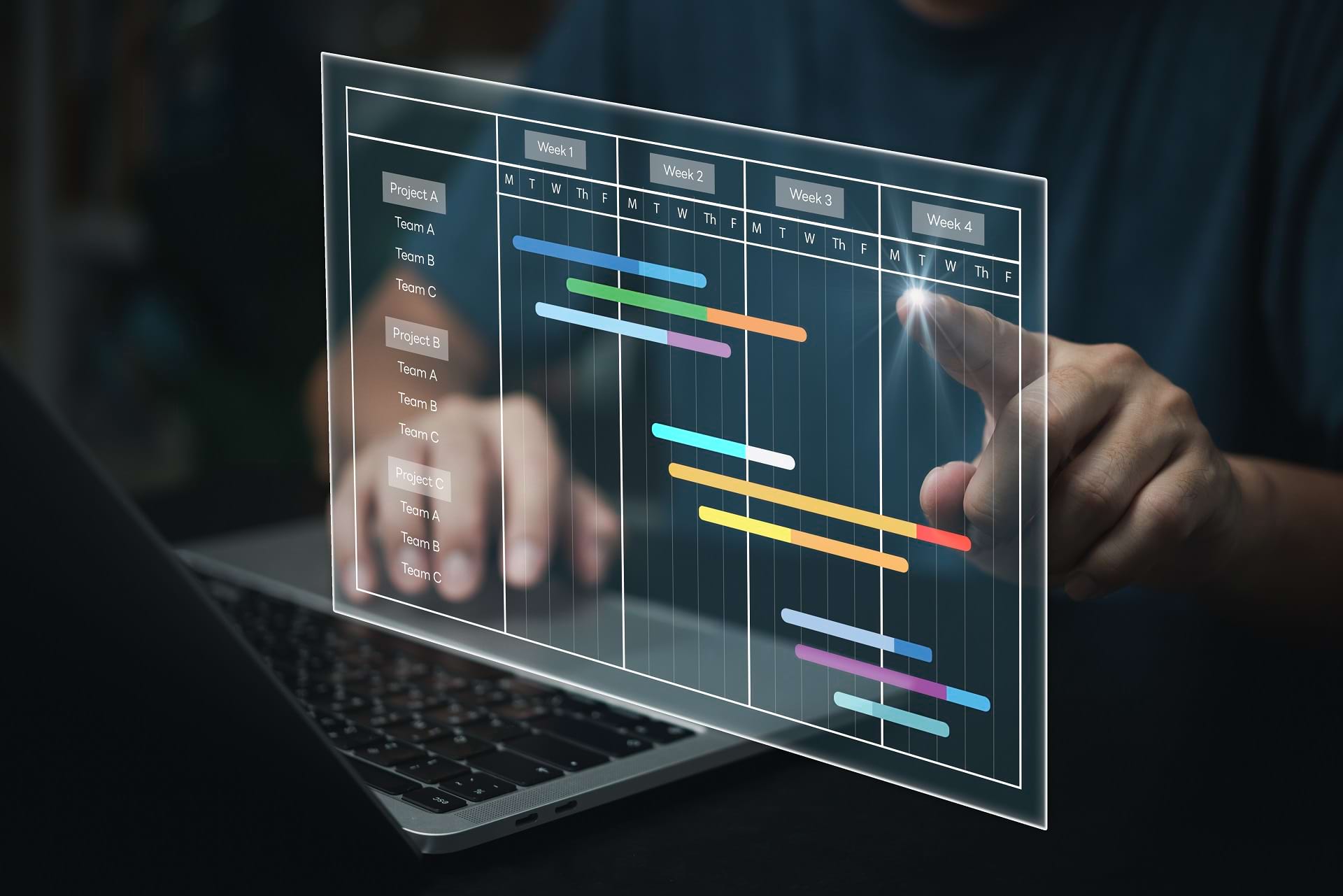

Use case: – Centralized Digital platform for facility planning, scheduling & report management (Brix Lab management module)

Goal: – Achieve centralized planning, scheduling & reporting which gives transparency and process automation by adapting the existing test processes.

Challenges: – The validation process is slowed down by complex departmental manual processes, manual planning, laboratory scheduling, and report preparation. Additionally, each team handles their testing process according to its own format.

Solution :- iASYS offered a Lab management solution ( BRIX LAB) to standardize planning, scheduling & reporting format.

Results :- Implemented client test process automation, reducing cycle time, eliminating redundancies, and establishing a knowledge repository for efficient knowledge management.