Advanced Motor Test Bench Upgradation for Comprehensive EV Drive Cycle Validation

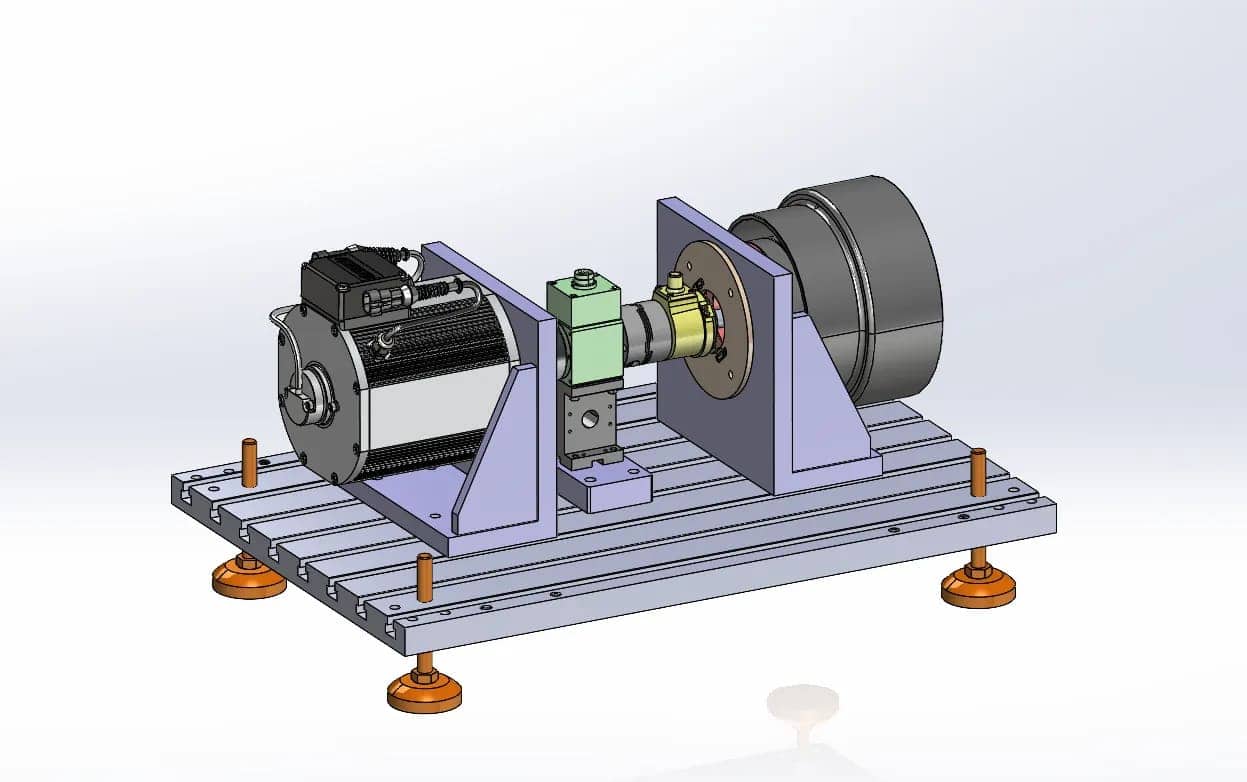

Use case: –Upgradation of an EV motor test bench to perform RLS testing, standard drive cycle validation (IDC & WMTC), and bi-directional motor testing directly at the motor level.

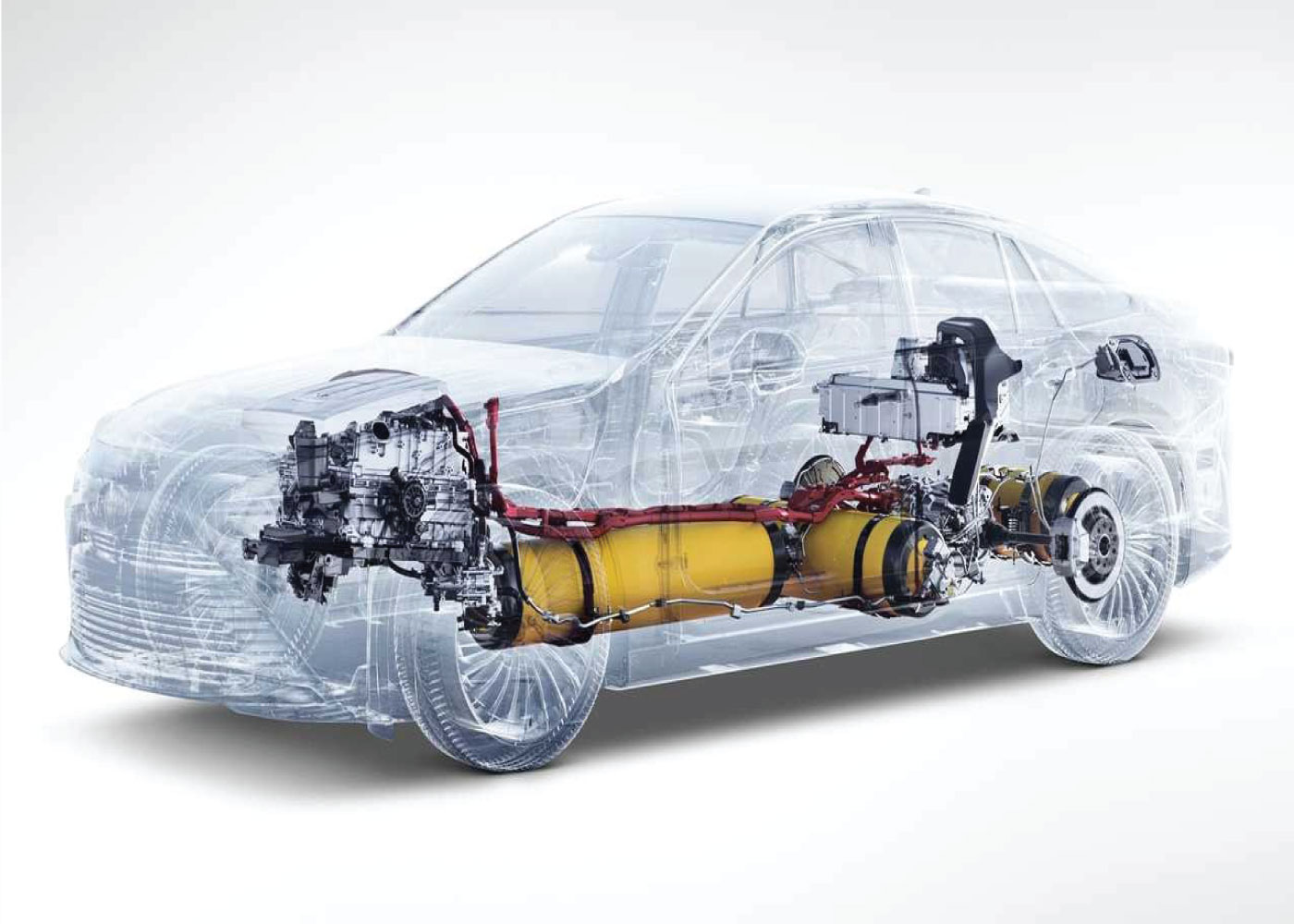

Goal: –To reduce dependency on vehicle-level testing by enabling accurate, automated, and comprehensive motor-level validation with faster data analysis and improved test efficiency.

Challenges:-The customer required RLS testing at the motor dyno level, support for multiple drive cycles, faster data processing, and bi-directional rotation capability, all within the existing test infrastructure.

Solution:-iASYS developed an enhanced EDC Controller with RLS functionality and upgraded the test bench using the Orbit EV Platform, integrating a Nidec Drive, automated analysis scripts, and real-time data acquisition tools.

Results :-Reduced vehicle-level testing efforts by 25–30%, shortened product development timelines by 20–25%, and accelerated data analysis by 60%, enabling more efficient, flexible, and accurate EV motor testing.