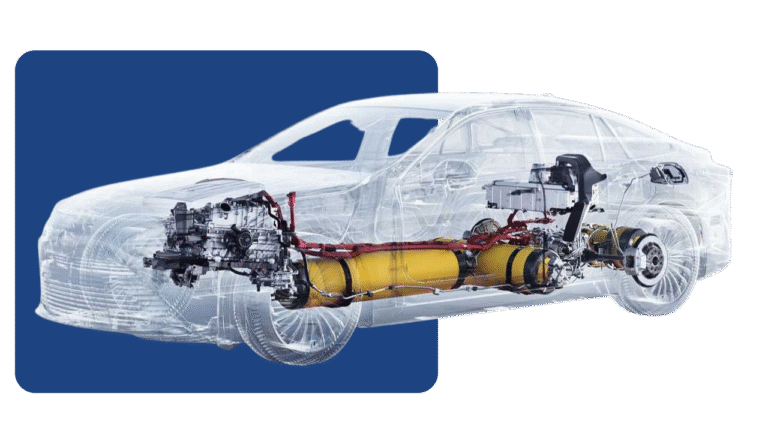

Fuel Cell & Electrolyser

Testing Solutions

Home > Solution > Fuel Cell & Electrolyser Testing Solution

Testing the future of zero-emission power.

ALWAYS AT THE SIDE OF OUR CUSTOMERS

Challenges

Developing hydrogen energy solutions is complex and demanding. Inaccurate testing, integration issues, and safety challenges slow down innovation. Without a scalable, reliable platform, zero-emission progress is at risk.

Pain Points

- 70% of fuel cell developers struggle with accurate and repeatable testing due to the complexity of hydrogen systems.

- 60% of R&D teams require scalable and flexible test systems to accommodate different fuel cell and electrolyser technologies.

- Strict global safety regulations demand advanced monitoring and fail-safe mechanisms to ensure safe hydrogen testing environments.

- Data inconsistency and system integration challenges slow down innovation in fuel cell and electrolyser development.

- Heterogeneous devices and measurement techniques adds complexity of the test system.

Remedies

Orbit H₂ – a next-generation Fuel Cell & Electrolyser Testing System, integrating German engineering precision with iASYS automation expertise. With a scalable, modular design, highly accurate measurement capabilities, and compliance with global safety regulations, Orbit H₂ enables seamless fuel cell & electrolysers testing for R&D, validation, and production.By providing automated test execution, real-time diagnostics, and multi-fuel compatibility, We empowers fuel cell manufacturers to develop hydrogen solutions faster, safer, and more efficiently.

- Midi: Supports single cells and small stacks up to 1 kW.

- Maxi: Designed for fuel cell stacks & systems up to 25 kW with endurance trials.

- Wide Range of Humidification & temperature control .

- Electrochemical Impedance Spectroscopy (EIS) & Gas Chromatography (GC) for precise analysis.

- HIL (Hardware-in-the-Loop) Interface for real-time simulation and control.

- House-in-House Design ensures independent operation without reliance on facility infrastructure.

- Leakage detection & emergency shutoff mechanisms for hydrogen safety.

- Configurable test setups with options for anode/cathode humidification, extra gas supply lines, and cooling systems.

- Independent operation with external simulation system integration

- Fully automated test execution and data acquisition.

- Multi-screen workstations for real-time visualization.

- Integration with external devices (temperature controllers, climate chambers, high-temperature furnaces, etc.)

Key Features

Featured Insights

Let's Solve it together

Struggling with complex Testing and Validation tasks?

They trust us