The automotive industry is evolving at an unprecedented pace. Electrification, connected vehicles, software-driven architectures, and stricter regulatory requirements are fundamentally changing how vehicles are developed and validated. As OEMs and Tier-1 suppliers scale up EV battery, engine, motor, and full-vehicle testing, they face an explosion of data, increased operational complexity, and mounting pressure to reduce development timelines and costs.

In such high-volume testing environments, disconnected tools, spreadsheets, and legacy systems fail to deliver speed, accuracy, or visibility. What the industry now demands is a Smart Solution for Vehicle Data Management—a unified platform that brings together testing processes, data, analytics, and lab operations under one ecosystem. The BRIX Platform by iASYS addresses this need by acting as a next-generation Vehicle Testing Management System purpose-built for EV and ICE programs.

This blog explains why BRIX has become essential for organizations handling large-scale EV battery, engine, motor, and vehicle testing—and how it enables measurable reductions in development cost while improving validation efficiency

The New Reality of High-Volume Vehicle Testing

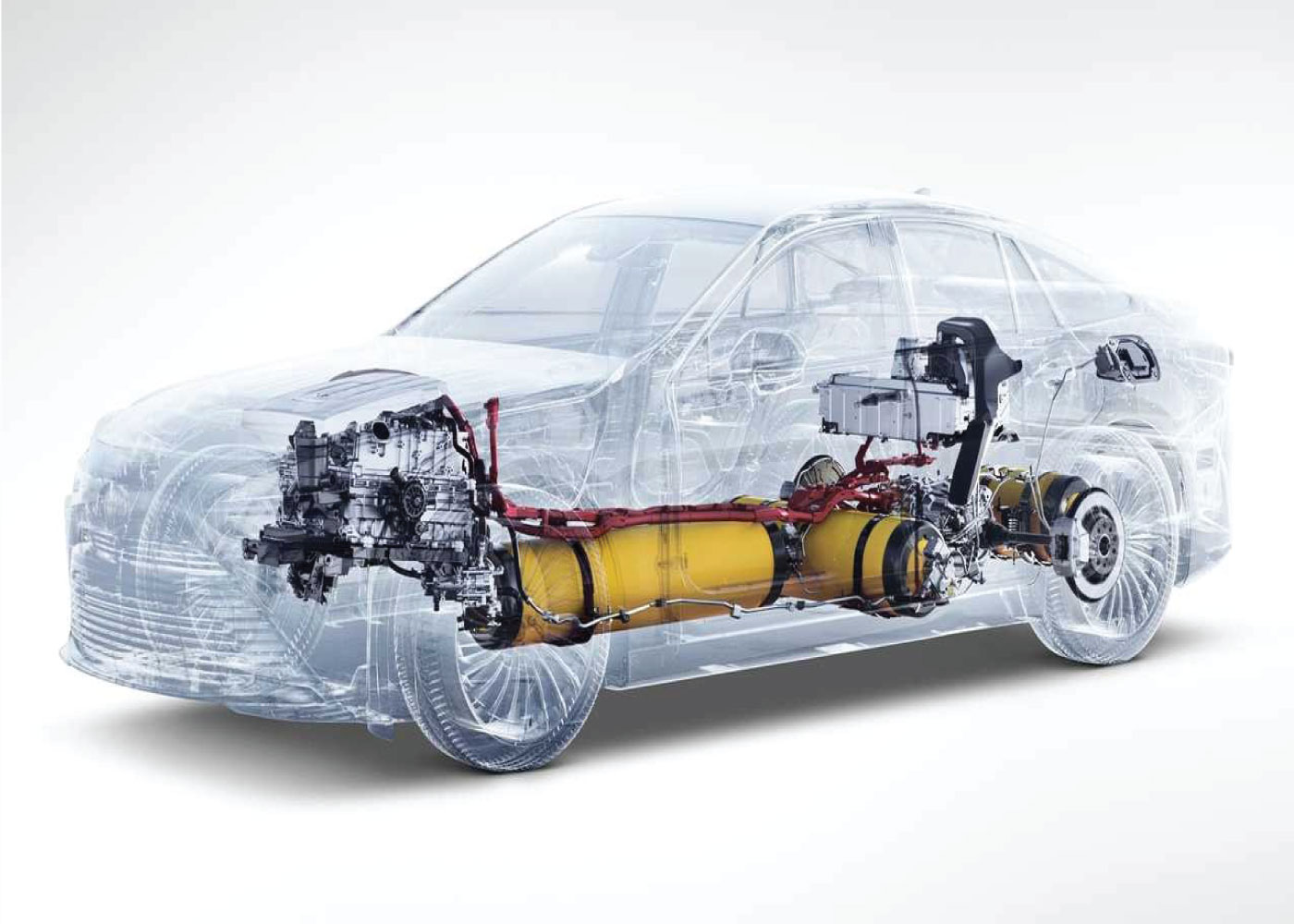

Modern vehicles are no longer evaluated only on mechanical performance. EVs and advanced ICE vehicles require extensive validation of batteries, motors, engines, power electronics, control software, and integrated vehicle systems. Each test cycle generates massive datasets across different labs, test beds, and geographies.

Key challenges faced by testing and validation teams include:

- Rapid growth in EV battery and motor test data volumes

- Parallel testing across multiple labs and facilities

- Limited visibility into historical test results

- Slow data retrieval and analysis

- Inefficient coordination of assets, manpower, and schedules

Without a unified Centralised Data Management System (CDMS), organizations struggle with data silos, delayed insights, duplicated testing efforts, and rising operational costs.

BRIX Platform: A Unified Foundation for Vehicle Validation

The BRIX Platform is a web-based digital transformation solution designed specifically for automotive OEMs and validation teams. It consolidates development planning, laboratory operations, and test data analytics into a single, scalable ecosystem.

BRIX supports:

- Onboard data & process management for EV / ICE programs

- Centralized lab and asset management

- Advanced analytics for historical and live test data

- Scalable data ingestion and storage

- Role-based applications tailored to engineers, managers, and decision-makers

By transforming fragmented validation workflows into connected intelligence, BRIX enables faster decisions and more efficient testing cycles.

Streamlining Test Lab Operations with BRIX-Lab

Challenges in Traditional Test Lab Management

In many organizations, test labs operate without a centralized control system. This results in poor coordination, underutilized assets, and frequent delays. Common issues include:

- Manual and untracked test request processes

- Scheduling conflicts between teams and projects

- Limited visibility into asset availability and calibration status

- Downtime caused by weak issue tracking mechanisms

Industry observations indicate that a majority of validation labs lose productive testing hours due to inefficient test request handling, resource conflicts, and unplanned downtime.

How BRIX-Lab Solves These Issues

BRIX-Lab is a core module of the BRIX Platform that functions as a comprehensive Vehicle Testing Management System for lab operations. It centralizes test requests, scheduling, assets, and issue tracking into one interface.

Key capabilities include:

- Digital submission and tracking of validation test requests

- Intelligent scheduling of test beds, equipment, and manpower

- Real-time visibility into asset utilization and availability

- Tracking of calibration, maintenance, and issue status

- Custom dashboards for lab managers and stakeholders

By improving coordination and visibility, BRIX-Lab significantly increases lab productivity and reduces avoidable downtime.

Data-Driven Validation with BRIX-Lite

The Need for an Engine and Vehicle Testing Data Solution

Engine, motor, and vehicle testing programs generate highly complex datasets. Without a modern Engine testing data management solution, validation teams face:

- Scattered and unstructured test data

- Long turnaround times for data retrieval

- Static and inflexible reporting formats

- Limited ability to identify trends or anomalies

These challenges slow down engineering decisions and increase development risk.

BRIX-Lite: Centralized Analytics for Faster Insights

BRIX-Lite is a web-based analytics module built on ASAM-ODS standards, designed specifically for product validation and verification workflows. It acts as a powerful EV testing data management platform for engineers and analysts.

With BRIX-Lite, teams can:

- Search and retrieve historical test data within seconds

- Analyze engine, motor, and vehicle datasets using interactive visualizations

- Generate flexible reports tailored to project needs

- Identify trends, deviations, and performance gaps early

As an advanced Engine testing data management solution, BRIX-Lite accelerates insight generation and improves decision quality across testing programs.

Managing EV Battery and Motor Data at Scale with D-BRIX

The Data Challenge in Battery and Motor Testing

EV battery and motor testing produce continuous, high-frequency datasets that grow rapidly over time. Legacy systems struggle with:

- Slow data ingestion and retrieval

- High infrastructure and maintenance costs

- Disconnected storage across teams and locations

- Limited support for analytics and AI workflows

This makes scalability and performance critical requirements for modern testing environments.

D-BRIX: A Scalable Data Management Platform for Vehicles

D-BRIX is a distributed and scalable Battery testing data management platform designed to handle massive data volumes efficiently. It also supports motor and vehicle datasets, making it a robust Motor testing data management platform.

Core strengths of D-BRIX include:

- Distributed architecture for high-volume data handling

- Optimized data import, storage, and processing

- Smart metadata-driven search and retrieval

- Parallel execution and near-data processing

- Readiness for advanced analytics and AI/ML workflows

As one of the best battery testing data management platforms, D-BRIX enables faster insights while keeping operational costs under control.

One Platform for EV, ICE, and Hybrid Validation

The BRIX Platform is designed to support diverse vehicle programs without the need for separate systems. It enables consistent In-Vehicle Data and Process Management across EV, ICE, and hybrid platforms.

Key advantages include:

- Unified workflows for battery, motor, engine, and vehicle testing

- Common data models for benchmarking and comparison

- Flexibility to adapt to evolving vehicle architectures

- Seamless integration of historical and current test data

This unified approach makes BRIX a future-ready Smart Solution for Vehicle Data Management.

Core Capabilities That Deliver Measurable Value

BRIX supports the complete validation lifecycle through integrated applications:

Test Plan (DVP&R) Management

A structured approach to defining, organizing, and tracking test plans, ensuring traceability between requirements, tests, and results.

Scheduler

An intelligent scheduling tool to plan and monitor tasks, test slots, and resource allocation over time.

Report Management

A connected reporting system to create, manage, and distribute insights-driven reports efficiently.

Asset Management

Centralized management of lab assets, equipment, and calibration data to improve utilization and reliability.

Issue Management

A systematic framework to capture, classify, resolve, and track testing-related issues across programs.

Utilization Dashboards

Customizable visual dashboards that provide real-time visibility into lab performance, asset usage, and efficiency metrics.

Together, these features help organizations lower development costs, reduce delays, and improve validation throughput.

Why BRIX Is Critical for High-Volume Testing Programs

For organizations managing large-scale validation programs, BRIX delivers value by functioning as:

- A unified Vehicle Testing Management System

- A modern Engine testing data management solution

- A scalable EV testing data management platform

- A robust Battery testing data management platform

- A centralized Centralised Data Management System (CDMS)

- A future-ready platform for In-Vehicle Data and Process Management

By eliminating silos and connecting data, processes, and teams, BRIX turns testing operations into a strategic advantage.

Conclusion

Transforming Vehicle Testing into a Competitive Edge

As vehicle programs grow in complexity and scale, testing and validation efficiency will define market success. Organizations that rely on fragmented systems will continue to face delays and rising costs. Those that adopt integrated platforms like BRIX gain speed, control, and insight.

The BRIX Platform enables OEMs and Tier-1 suppliers to manage high-volume EV battery, motor, engine, and vehicle testing through a single, scalable ecosystem. By combining lab management, analytics, and big data processing, it delivers faster validation cycles, reduced costs, and data-driven confidence.

For organizations seeking a Scalable data management platform for vehicles that supports both current and future mobility programs, BRIX is no longer optional—it is essential.