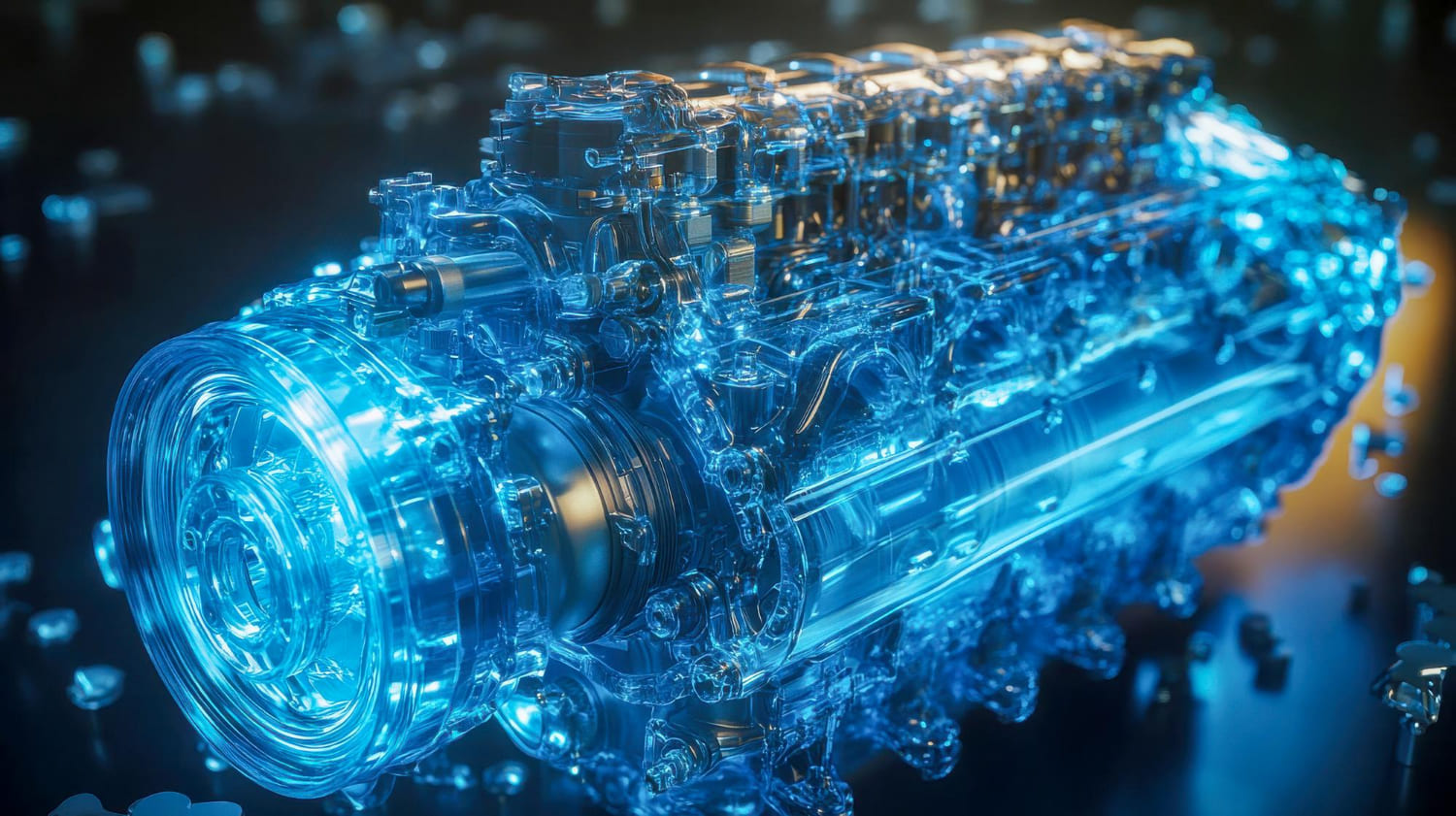

As the automotive industry moves toward decarbonization, the discussion over hydrogen ICE vs fuel cell and electric powertrains heats up. While battery electric vehicles (BEVs) dominate the news, hydrogen internal combustion engines (ICEs) are quietly emerging as a possible alternative. With breakthroughs in testing, safety, and scalability, Hydrogen ICE: a green engine for the future may play an important part in sustainable mobility.

Why Hydrogen ICE Matters

Hydrogen ICE technology builds on the familiarity of classic combustion engines while substituting fossil fuels with clean-burning hydrogen. This enables manufacturers to modify existing platforms without reinventing the wheel. Unlike batteries, which require rare earth minerals and recycling solutions, hydrogen offers scalability and rapid refueling, coinciding with the worldwide demand for cleaner transportation.

The Promising Future of Hydrogen Combustion Engines

Hydrogen ICEs offer several unique benefits:

- Decarbonisation Potential: Hydrogen ICE can be part of transport decarbonisation by significantly cutting CO2 emissions.

- Scalability: Existing engine platforms and supply chains can be adapted with minimal modifications.

- Fast Refueling: Comparable to today’s gasoline and diesel vehicles, making them practical for long-haul transport and commercial fleets.

Challenges Slowing Down Hydrogen ICE Development

Despite its potential, hydrogen ICE development faces challenges that cannot be ignored:

- Combustion Efficiency: Hydrogen’s wide flammability range makes combustion optimization difficult.

- Emission Control: While CO2 is reduced, managing NOx emissions requires advanced calibration.

- Safety Risks: Hydrogen is highly flammable, requiring specialized infrastructure and safety measures.

- Testing Limitations: Many outdated test setups are not designed for hydrogen, slowing R&D and compliance efforts.

Without modern testing solutions, manufacturers risk delays, higher costs, and regulatory setbacks—critical barriers in the race toward clean mobility.

Powering the Future with Safe, Efficient and Scalable Hydrogen ICE Testing

To overcome these barriers, advanced testing solutions are essential. IASYS, a leader in powertrain and engine testing, has developed Hydrogen ICE Testing Solutions designed to validate and optimize hydrogen-powered engines.

Key Testing Capabilities

- Hydrogen ICE Performance Testing: Complete combustion analysis, power output evaluation, and efficiency measurement.

- Combustion Optimization: Air-fuel ratio (A/F) and λ sensor integration, abnormal combustion suppression, supercharging, direct injection, and hydrogen fuel map calibration.

- Hydrogen Safety Systems: Optimized test environments with safety measures for handling high-moisture exhaust gases.

- Upgraded Test Facility: Outdated test facilities don’t need to be scrapped—they can be modernized with hydrogen safety systems, explosion-proof design, ventilation, and emergency controls. With these upgrades, an ICE lab can be transformed into a state-of-the-art H₂ ICE testbed, ready to support the future of hydrogen mobility with iASYS Automation.

- Multi-Fuel Compatibility: Upgrade existing gasoline/diesel engine testbeds for hydrogen use with minimal investment.

- Automated Testing & Data Analysis:Orbit-H2 software for real-time monitoring, compliance validation, and automated execution.

By leveraging its Orbit Automation Platform, IASYS ensures a smooth transition from conventional ICE testing to hydrogen-compatible solutions, enabling manufacturers to achieve safety, scalability, and compliance.

Hydrogen ICE vs Electric Powertrains – Who Wins?

The big question remains: Hydrogen ICE – can it compete with electric powertrains?

- Electric Vehicles (EVs): Best suited for passenger cars and urban transport due to high energy efficiency and growing charging networks.

- Hydrogen ICEs: More competitive for heavy-duty transport, commercial fleets, and regions lacking robust EV charging infrastructure.

Hydrogen ICE vs Electric Powertrains – Key Differences

Feature / Factor | Hydrogen ICE (Internal Combustion Engine) | Electric Powertrain |

Fuel Source | Hydrogen gas (burned in modified ICE) | Electricity (stored in batteries) |

Efficiency | Moderate (30–40%) | High (70–95%) |

Refueling / Charging | Fast (similar to petrol/diesel – minutes) | Slow (30 min–several hours) |

Infrastructure | Needs hydrogen production & fueling stations | Needs charging stations & grid upgrades |

Emissions | Near-zero (mainly water vapor, small NOx) | Zero tailpipe (if renewable electricity used) |

Applications | Heavy-duty transport, long-haul, fleet vehicles | Passenger cars, urban mobility |

Scalability | Easier transition from existing ICE tech | Requires full electrification shift |

So,both technologies will likely coexist, complementing each other in the global decarbonization journey. While EVs dominate short-distance transpor, hydrogen ICE can be part of transport decarbonisation in sectors where electrification is less practical.

Conclusion

Hydrogen ICE technology is not just a transitional solution—it is a green engine to drive into the future. While electric vehicles will continue to dominate certain segments, hydrogen ICEs offer scalability, flexibility, and practicality for industries where batteries fall short.

With innovations in Hydrogen ICE Testing, manufacturers now have the tools to overcome safety, compliance, and efficiency challenges. The result? A more balanced future where both hydrogen and electric powertrains work hand in hand to power sustainable mobility.

FAQs on Hydrogen ICE vs Electric Powertrains

1. What is a hydrogen internal combustion engine (Hydrogen ICE)?

A hydrogen internal combustion engine is similar to a traditional petrol or diesel engine but runs on hydrogen fuel. It burns hydrogen in the combustion chamber to produce power, offering a cleaner and greener alternative to fossil fuels

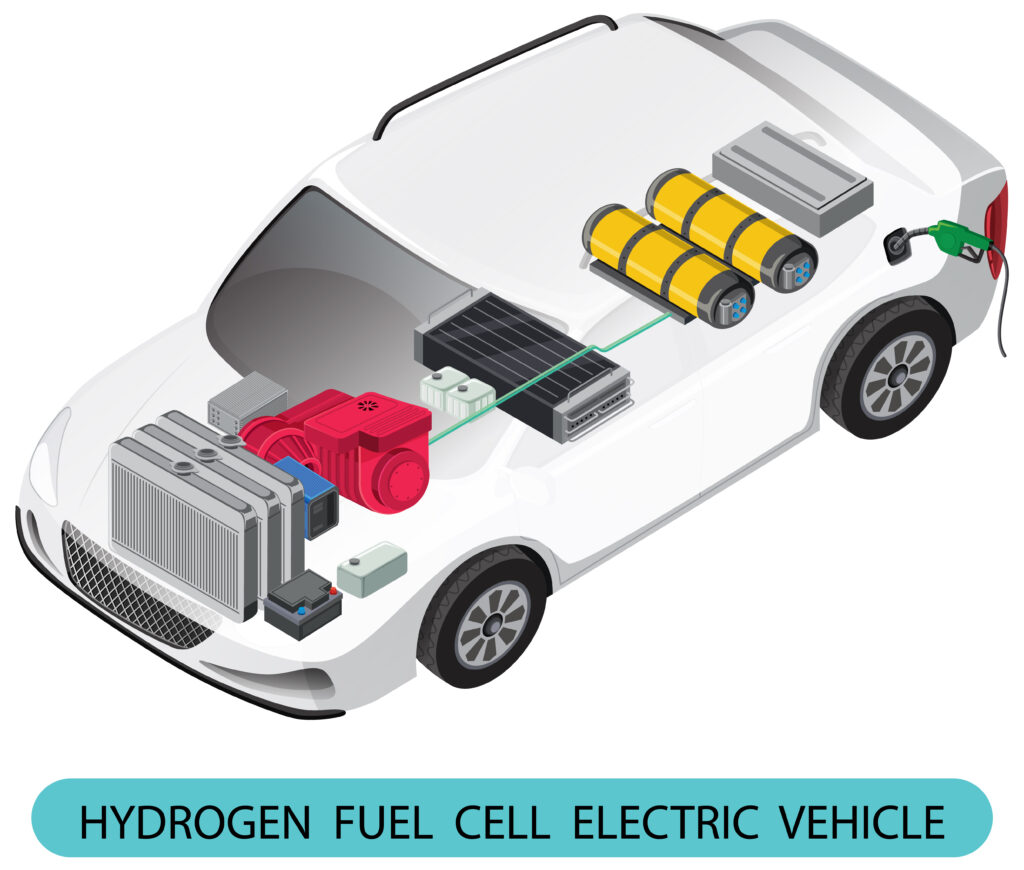

2. Hydrogen ICE vs fuel cell – what’s the difference?

Hydrogen ICE burns hydrogen directly in an engine, much like gasoline. Fuel cells, on the other hand, generate electricity through a chemical reaction between hydrogen and oxygen. While fuel cells are more efficient, Hydrogen ICEs are easier to adapt using existing engine platforms.

3. Can hydrogen ICE be part of transport decarbonisation?

Yes, hydrogen ICE can be part of transport decarbonisation by reducing CO2emissions significantly. With rapid refueling and scalability, it’s particularly useful for heavy-duty trucks, buses, and industrial transport where battery solutions may fall short.

4. What are the challenges of hydrogen combustion engines?

The main challenges include managing NOx emissions, ensuring combustion efficiency, handling hydrogen safely, and updating test facilities to meet hydrogen-specific requirements.

5. Hydrogen ICE: can it compete with electric powertrains?

Hydrogen ICEs are highly competitive in sectors like long-haul transport, commercial fleets, and areas without EV charging infrastructure. Electric powertrains are better suited for passenger cars and urban commuting. Both will likely coexist to support global decarbonisation goals.

6. Why is hydrogen ICE testing important?

Testing ensures hydrogen engines are safe, efficient, and compliant with emission regulations. Advanced testing systems help manufacturers optimize combustion, evaluate performance, and integrate hydrogen safely into existing testbeds.

7. Is hydrogen ICE a green engine to drive into the future?

Yes. Hydrogen ICE is a green engine to drive into the future because it provides a practical, scalable, and cost-effective way to reduce emissions in transportation while leveraging existing engine technologies.

HOW IASYS CAN HELP: In ICE to H2 ICE transformation

To overcome the transformation iASYS offers scalable and customize Testing solution which can help you to transform from ICE to H2 ICE test system in very minimal changes in Automation by upgrading the Safety Infrastructure according to Hydrogen testing.

Hydrogen ICE or Electric Powertrain – Which solution fits your business needs?

Let IASYS experts help you identify the right testing solutions for your mobility journey.

Connect with Our Team