A Japanese automotive OEM was struggling with inconsistent, siloed data across different teams, ultimately slowing down their vehicle development process. Using a Neo4j knowledge graph for standardized metadata, the manufacturer made cross-enterprise data exchange seamless and sped up its product validation life cycle.

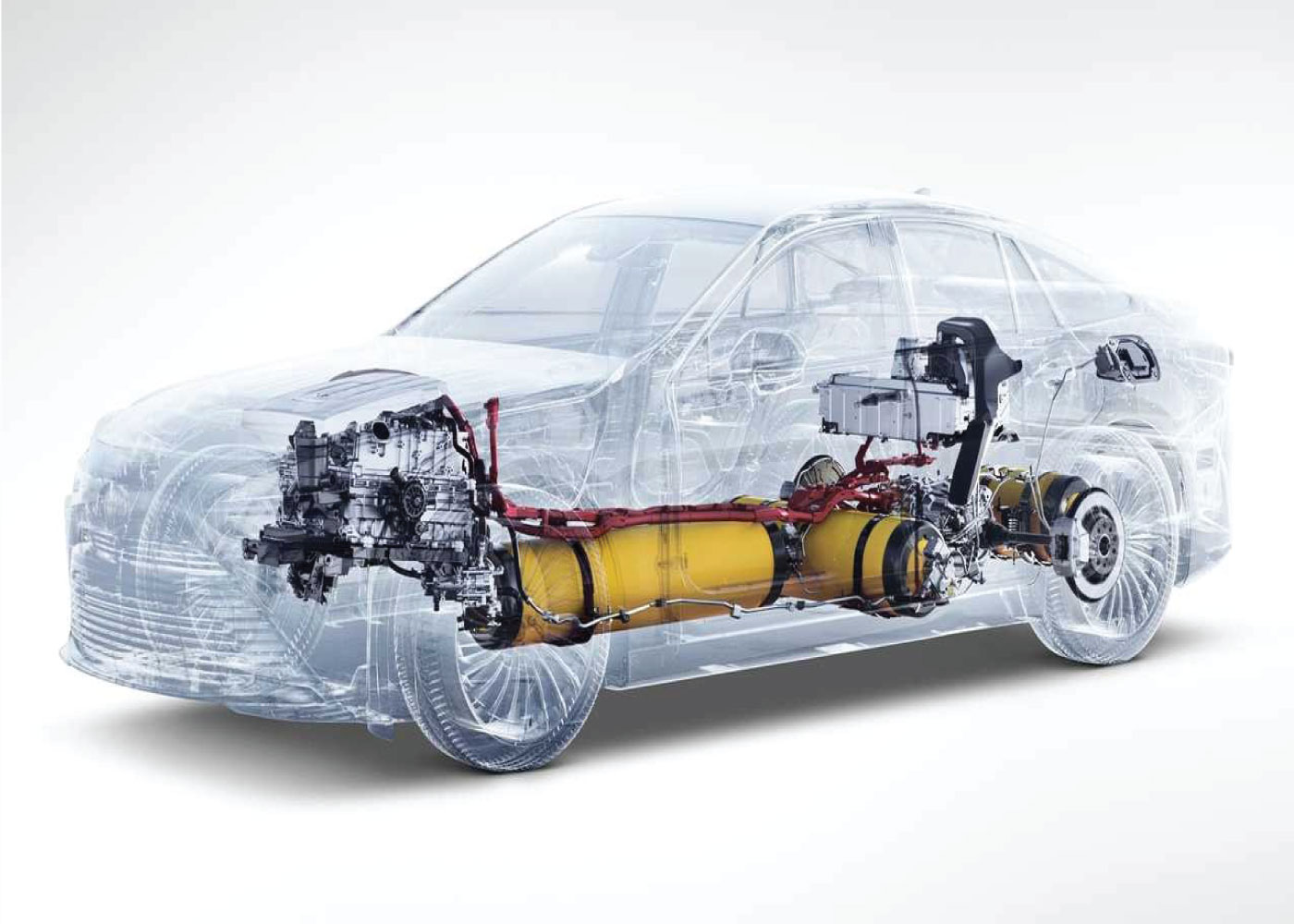

Why the BRIX Platform Is Essential for High-Volume EV Battery, Engine, and Vehicle Testing

The automotive industry is evolving at an unprecedented pace. Electrification, connected vehicles, software-driven architectures, and stricter regulatory requirements are fundamentally